Tackling regional haze reduction more effectively

But closing coal plants is one thing. Dealing with the leftovers is quite another. There are hundreds of millions of tons of coal ash in the U.S. in waste piles and in ash ponds where coal ash is mixed with water. Wind and evaporation can spread contaminants from coal ash a considerable distance across the surrounding landscape.

That’s a problem for the nation and the national parks in particular. Contaminants in the air cause haze, reducing visibility considerably. A variety of solutions have emerged to lessen haze and curtail pollutants.

Haze is a problem

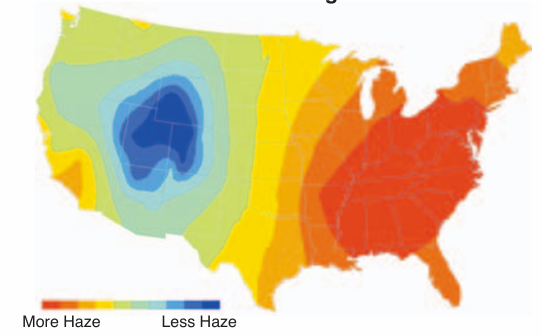

The almost 300 million visitors to U.S. parks and wilderness areas don’t always get to see the spectacular vistas they expect. White or brown haze often hangs in the air and blurs the view. Instead of around 100 miles of visibility in clear air, tourists see as little as 15 miles, at times, in some parts of the eastern states. It’s a little better in the western states but not by much.

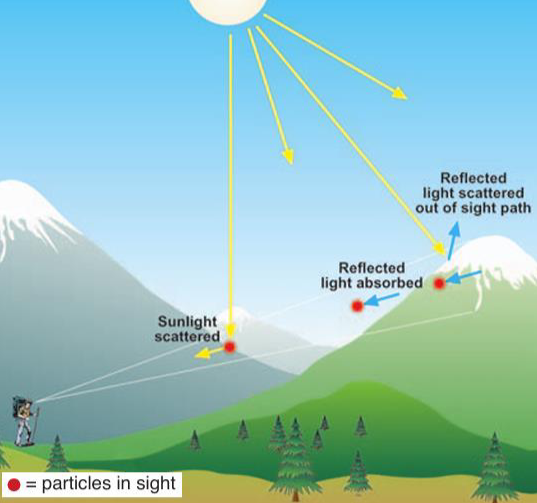

Haze forms when particulate in the air reflects, absorbs, or scatters sunlight. Courtesy of the National Parks Conservation Association.

Haze occurs when sunlight encounters particles in the air that absorb or scatter light before it reaches the observer. Some is natural occurring, but the bulk is man-made. Coal plants are getting much of the blame. As well as impairing visibility, some of the pollutants that form haze are linked to health problems such as respiratory illness and environmental damage by contributing to acid rain formation.

To beef up its enforcement powers from the Clean Air Act, the U.S. Environmental Protection Agency (EPA) issued the Regional Haze Rule in 1999 (40 CFR 51.300): It targets “visibility impairment that is caused by the emission of air pollutants from numerous sources located over a wide geographic area.”

It called upon states to develop programs to improve visibility in national parks and wilderness areas affected by air pollution. Of most relevance to coal ash ponds, the ruling sought to contain the spread of haze caused by the spread of particulate matter (PM) in the PM 2.5 to PM 10 range. Coal ash ponds and impoundment sites were found to be a major source of PM 2.5 particles due to evaporation.

The ruling ordered state and federal agencies to address visibility in 156 national parks and wilderness areas such as the Grand Canyon, Yosemite, the Great Smokies and Shenandoah. States are required to submit state implementation plans (SIPs) that target better control of air emissions towards the goal of achieving natural visibility.

The first phase of implementation of the Regional Haze Rule brought tangible gains.

“Data show that state efforts have achieved significant improvements in visibility throughout the country with visual range improving by 20 to 30 miles in national parks and wilderness areas between 2000 and 2015,” said EPA Administrator Andrew Wheeler. “We are following our Regional Haze Roadmap to build on lessons learned during the first implementation period and provide enhanced support for states during the second implementation period.”

A second phase of enforcement entails new SIPs from most states with deadlines for compliance ranging throughout the decade. Thus, a wave of remediation and enforcement actions can be expected across the country. Ulla Reeves, the interim director of the National Parks Conservation Association’s Clean Air Program, noted modest air quality improvements over the last five years in haze levels. However, 98% of parks still suffer from hazy skies. Hence, coal plants and other industrial facilities are bracing for another round of Regional Haze Rule activity.

This aerial view shows cleanup work taking place at the Tennessee Valley Authority’s Kingston Fossil Plant in 2009.

Haze remediation actions

A number of technologies and programs have been introduced to address haze and coal ash pond cleanup. The Tennessee Valley Authority (TVA), for example, took decisive action after a 2008 dike failure at an ash pond at its Kingston coal plant. Following the disaster, the EPA issued new rules to regulate coal combustion ash such as corrective actions during and after closure, technical standards for pond linings, and requirements for inspection, monitoring, recordkeeping, and reporting.

In response, TVA developed the Advanced Technology for Impoundment Monitoring (ATIM) system to manage its coal ash storage sites. The authority also utilizes compaction technology and maps each layer of coal ash that is placed into TVA’s dry storage landfills to ensure their safety and stability. The result: TVA now recycles 82% of the coal ash it produces annually. Much of it is used to manufacture wallboard and cement.

Other industry solutions gaining favor include better liners for coal ash ponds. ProtectGD, for example, offers a geopolymer that can be used in liners to prevent heavy metals in coal ash from leaching into groundwater. It is also used to convert fly ash into construction materials to be used for road bases, land reclamation, and airport runways.

Another approach from Aquatronox is known as electrochemical oxidation. It uses a pre-determined reaction using a low DC electrical current to change the particle surface charge, allowing suspended matter to form an agglomeration and subsequent removal from the water solution.

Minimizing evaporation of haze-causing particles

Perhaps the most common approach to haze mitigation in existing coal ash points is the deployment of snowblowers. Many utilities and power plant owners position snowmaking cannons around ponds, which are basically modifications of the equipment used on mountain slopes of ski resorts to create snow. The idea is to blow water at high pressure to minimize the evaporation of particulate matter. They may be proven at snowmaking but they are less than ideal at containing regional haze.

RWI Enhanced Evaporation has devised a different way of tackling the particulate matter draft from coal ash ponds. Its founder, atomic and molecular spectroscopist Robert Ballantyne Jr., conducted detailed testing on droplet coalescence and collision using a wind tunnel to uncover misconceptions related to snowblowers.

Misconception 1: Almost all droplets from a snowblower coalesce, which prevents the spread of particulate matter. This is false. Computational fluid design (CFD) imagery, high-speed cameras, and liquid chromatography reveal that converted snowmakers generate a dry aerosol plume that rises into the atmosphere.

“The powerful water jets produced by snowmakers create turbulence that destabilizes droplets, which then fracture into smaller droplets and dry out in flight,” said Ballantyne, President of RWI Enhanced Evaporation. “This creates a large particulate matter load in the atmosphere in violation of air quality standards.”

These cannons often emit droplets in the 50- to 150-micron range. Large droplets lead to a lot more collisions and a higher volume of particulate matter in the air. In response, manufacturers have released different nozzle and spraying configurations to lower the droplet collision rate, but the problem remains. Ballantyne found that only 18% of these droplets coalesce into larger droplets to contain particulate spread. The rest collide, get smaller, dry out, and create more haze, not less.

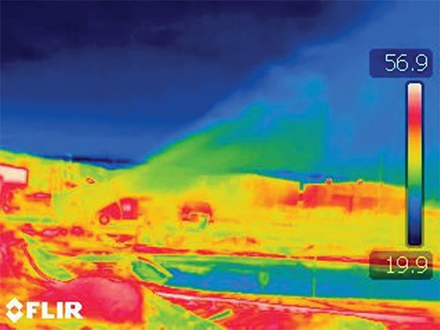

A pollution plume lofting into the atmosphere above a containment pond. Wet-bulb temperature is green colored. Blue is below wet bulb, indicating no water is left. The resulting dry particulate can be blown by the wind across a wide geographic area.

Misconception 2: By firing water at high velocity, snowblowers can prevent the spread of particulate. This is an incorrect idea. High velocity has been found to cause droplet destabilization as the droplets fracture into particles many times smaller. These smaller droplets generate a large particulate load that causes haze.

“The basic problem is that droplets are drying out in flight after destabilization,” said Ballantyne.

His team identified all the factors that increased the rate of droplet-to-droplet collision. The energy level of the spray largely determines the rate of droplet fracture. Further, the angle of spray needs to be controlled to prevent unnecessary turbulence. If the trajectory of water spray is more closely controlled, fewer collisions take place. The institution of such controls results in a major reduction in the pollution plume escaping into the atmosphere and far less spread of PM 2.5 into the environment.

“By controlling the droplet size and maintaining proper sedimentation rates, 700 tons per year of emissions from traditional containment solutions can be reduced to 120 pounds per year,” said Ballantyne. “This is well below the six tons required by New Source Review (NSR) levels.”

Traditional snowblowing solutions add to haze and worsen the problem by spreading haze-causing particulate for hundreds of miles around. Expect this source of haze to come in for extra attention during the second phase of Regional Haze Rule remediation and enforcement.

Landshark land-based evaporator units from RWI Enhanced Evaporation deployed around a coal ash pond to prevent the spread of particulate matter.

RWI offers a couple of solutions to the haze problem and to improve compliance with coal ash pond regulatory requirements. A trajectory or canon evaporator known as the Landshark 2.0 is a type of industrial spray evaporator that carries water on a ballistic path or trajectory arc above the ground surface, water, or a solid surface. Their advantage is a greater evaporation rate compared to pond-based evaporators. This type of industrial spray evaporation equipment is meant for sites with large areas of operation where the trajectory can be adjusted to operational constraints. They use a 4.5 hp engine instead of the usual 40 hp in a snowmaker. The Landshark 2.0’s center spray lance is designed with a precise air-to-water mixture, and tight control of droplet sizes and trajectory lengths for maximum pollution plume mitigation.

The PittBoss from RWI sits above the water or ash pond to reduce the amount of fluid that needs to be disposed of.

RWI’s PittBoss is a platform that sits two feet above the water or ash pond. It uses wave mathematics to cause a swell to peak and crash making droplets of the right size for proper sedimentation. This floating industrial evaporator sits directly on the surface of an impoundment or pond. It reduces the amount of fluid that needs to be disposed of and is an economical alternative to truck transport. While land-based evaporators are more prone to shut down due to wind gusts, this floating evaporator can continue to evaporate in the same conditions because the spray plume is closer to the pond surface and drops back into the pond instead of on surrounding vegetation.

Once in the pond, the location of the PittBoss can be adjusted to compensate for wind direction to maximize evaporation rates. (Evaporation rates depend greatly on weather conditions such as ambient temperatures, relative humidity, wind speed, etc.) It reduces energy consumption from 25 hp to 4.5 hp compared to a traditional snowblower. Additionally, it improves the evaporation rate as it uses a downdraft design that can take some ponds to a dry state while containing the dry aerosol drift commonly associated with larger horsepower evaporators. Downdraft evaporation allows complete control of the air velocity, droplet size and droplet flight time. This keeps the ion content in the water surface where the ion content is less likely to loft off.

Conclusion

The U.S. possesses a great many coal ash ponds. Poorly managed, they evaporate harmful particulate into the air that spoils the view in many national parks and contributes to a variety of health concerns. It is up to those owning the many remaining coal ash assets to responsibly take care of them using the latest technology.